GlassBuild 2025 Trends: How the Glass Industry is Evolving

At GlassBuild 2025 was full of exceptional advancements across the industry, with three themes being most repeated: thermal performance, bird safety, and handling efficiencies. The trends show how manufacturers continue to balance aesthetics, sustainability, and operational efficiency.

Thermal and Energy Performance Insulating Glass

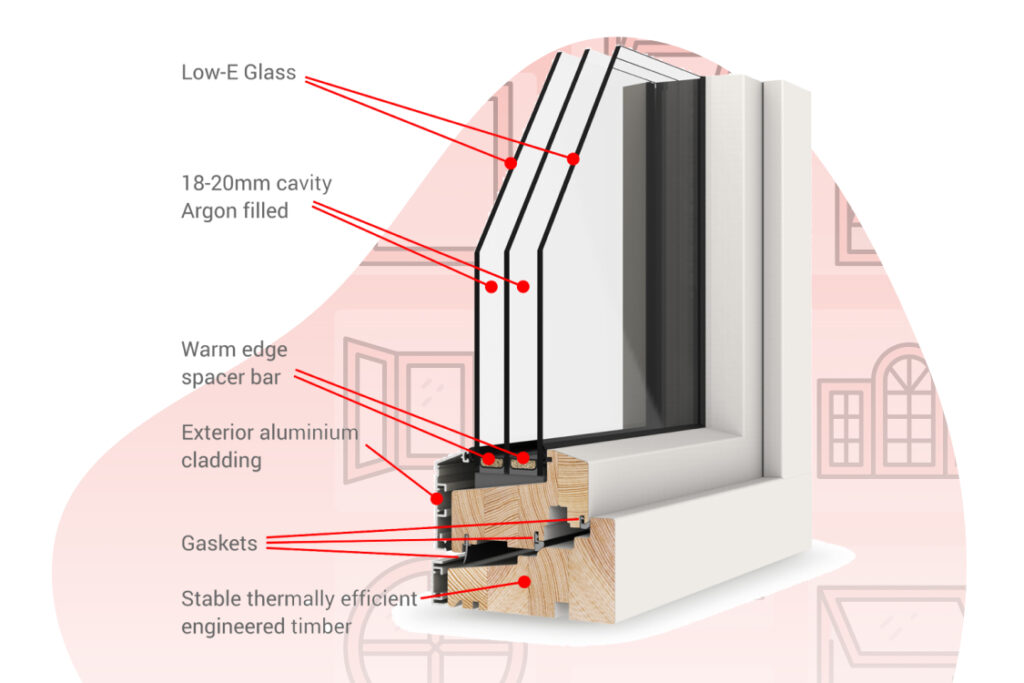

This year triple-pane insulated glass proved strong, indicating interest in energy-efficient building solutions. The continuing popularity of low-E solar control coatings reflects their importance in minimizing unwanted heat gain during the summer and heat loss during the winter, which lowers energy bills and enhances occupant comfort.

Material innovations are transforming the very construction of glass units. Thinner insulated glass reduces weight, which not only eases installation but also reduces structural load on framing systems. Meanwhile, advanced edge spacers now improve overall U-factor, insulation performance without increasing frame width.

One particularly notable development is the ability to upgrade from double- to triple-pane glass without changing the frame or adjusting overall thickness. This opens possibilities for retrofits and renovations that give older buildings to potential to better their thermal efficiency without extensive remodeling.

Bird-Friendly Glass Solutions

With growing environmental awareness, GlassBuild did not lack bird-safe glass solutions. Collisions with reflective glass are one of the leading causes of bird fatalities worldwide, prompting developers to seek functional yet aesthetic solutions.

Laser-etched or sandblasted patterns, including dots, lines, and frits on UV-reflective glass provide visible deterrents for birds without compromising transparency.

From residential and commercial buildings, these solutions are increasingly being applied in urban landscapes, green roofs, and public spaces, in keeping with a holistic approach to wildlife safety. Some companies showed integrated systems where the bird-friendly markers are factory-applied within insulated glass units, combining safety, durability, and ease of installation.

Improved Glass Handling

Efficiency and safety have been the center of much innovation in glass handling. Traditional glass handling involves considerable manual labor, posing risks of injury and product damage. Automation technologies now address both concerns, enabling faster, safer, and more precise operations.

For instance, the Billco x Kawasaki Robotics Arm shows how advanced automation can handle large and complex glass lites, including IGUs, laminated panels, and specialty glass, across a wide range of sizes. These systems reduce dependency on manual handling, provide consistent precision, and increase throughput, particularly in limited-space facilities.

Innovations shown included robotic stacking and retrieval systems, ergonomic lifting aids, and conveyor integrations that streamline the production flow from racks to shipping. Beyond efficiency gains, these technologies greatly minimize breakages and costs associated with them, while also improving worker safety.

Show Recap

GlassBuild 2025 highlighted a clear trajectory for the glass industry: integrated solutions that prioritize sustainability, safety, and operational efficiency. From triple-pane energy-efficient units to bird-safe glass and cutting-edge automation, companies are demonstrating how innovation can simultaneously serve people, the environment, and business objectives together.

With higher demands for smarter, greener, and safer building solutions, manufacturers are pushing the boundaries to deliver high-performance glass that meets the aesthetic and functional needs of tomorrow’s architecture.